Our Service

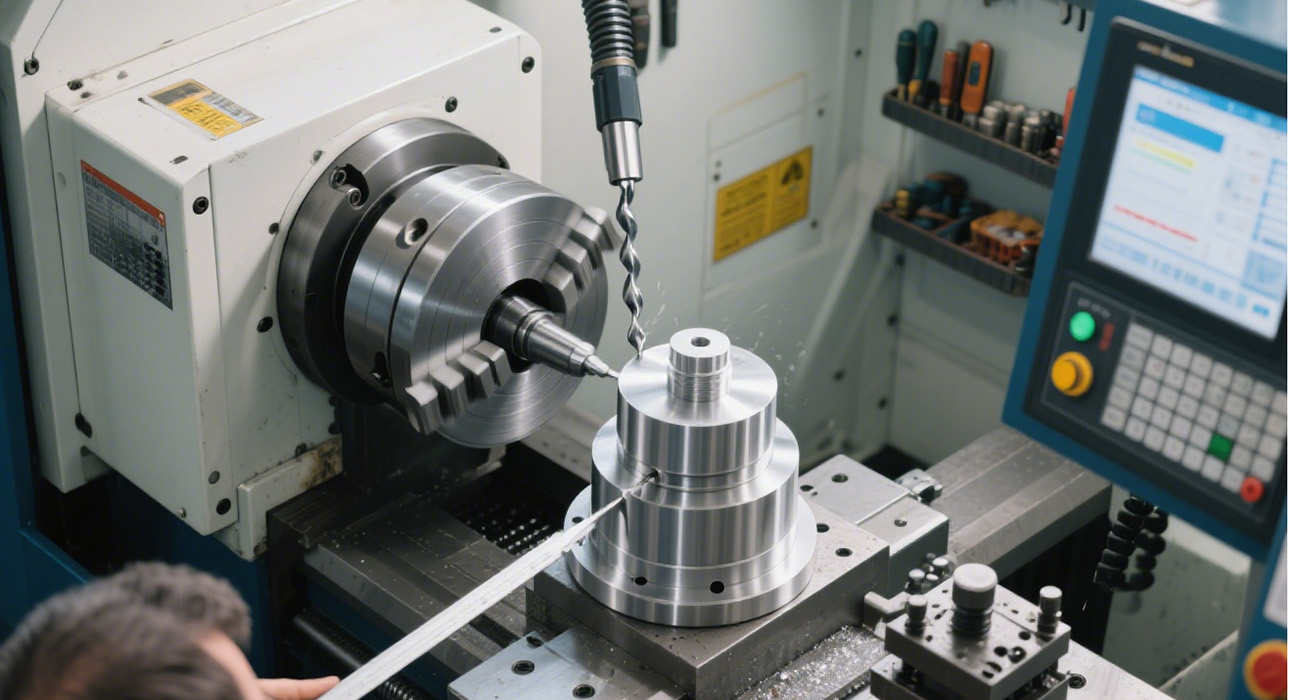

We are a renowned provider of CNC machining services, dedicated to delivering high-precision and top-quality machined parts. With a team of highly experienced technicians and state-of-the-art CNC equipment, we have been serving diverse industries for many years. Our commitment to excellence and customer satisfaction has made us a preferred choice for clients seeking reliable and accurate machining solutions.

Capabilities

Milling

We stock a range of metal materials that are suitable for various part applications and industries. Choose from aluminum, brass, low carbon steel, stainless steel, steel alloy, and titanium for turned parts.

Turning

Precision turning is another area of our expertise. Our CNC lathes can produce cylindrical parts with tight tolerances and excellent surface finishes. Whether it's small shafts or large spindles, we ensure the highest quality in every turn.

Drilling and Tapping

We offer precise drilling and tapping services to create holes and threads according to your exact specifications. Our advanced drilling equipment and techniques ensure accurate hole placement and clean, reliable threads.

Grinding

For parts that demand superfine surface finishes, our grinding services are second to none. Using high-precision grinding machines, we can achieve surface roughness values as low as you require, enhancing the performance and aesthetics of your components.

Materials We Work With

We have extensive experience working with a diverse range of materials, each chosen to meet the specific needs of your project.

| Material | Properties | Common Applications |

| Aluminum | Lightweight, good corrosion resistance, excellent machinability. | Aerospace, automotive, electronics. |

| Steel | High strength, good toughness, available in various grades. | Machinery, construction, tools. |

| Stainless Steel | Corrosion resistant, hygienic, suitable for harsh environments. | Medical, food processing, marine. |

| Brass | Good conductivity, corrosion resistant, easy to machine. | Electrical components, plumbing fixtures. common uses) |

| Copper | Excellent conductivity, ductile, used in various applications. | Electrical wiring, heat exchangers. |

| Titanium | High strength-to-weight ratio, corrosion resistant, biocompatible. | Aerospace, medical implants, sports equipment. |

Quality Assurance

Quality is the cornerstone of our CNC machining service. We have implemented a rigorous quality control system to ensure that every part meets or exceeds your expectations.

Incoming Material Inspection

All incoming materials are thoroughly inspected for quality and conformance to specifications. We use advanced testing equipment to verify material properties, ensuring that only the best materials are used in your parts.

In-Process Inspection

During the machining process, we conduct regular inspections to monitor the quality of the parts. Our technicians use precision measuring tools to check critical dimensions and tolerances, making adjustments as needed to maintain accuracy.

Final Inspection

Before shipping, each part undergoes a comprehensive final inspection. We use advanced metrology equipment, such as Coordinate Measuring Machines (CMMs), to ensure that all dimensions and tolerances are within the specified limits. Only parts that pass this strict inspection are delivered to our customers.

Certification and Traceability

We provide detailed inspection reports and certifications for each order, documenting the quality control process. Our traceability system allows you to track each part back to its raw material source and machining history, giving you complete confidence in the quality and integrity of our products.

Production Process

Design and Engineering

Our team of skilled engineers works closely with you to review and optimize your designs for manufacturability. We use the latest CAD/CAM software to create accurate machining programs, ensuring the best possible outcome for your project.

Material Preparation

Once the design is finalized, we carefully select and prepare the appropriate materials. We cut the raw materials to the required sizes and shapes, ready for machining.

Machining Operations

The parts are loaded onto our CNC machines, and the machining process begins. Our experienced operators closely monitor the machines to ensure smooth operation and adherence to the programmed instructions. We use advanced tooling and cutting strategies to achieve high quality and efficiency.

Quality Control and Inspection

As mentioned earlier, quality inspections are carried out at various stages of the production process. We ensure that any deviations from the required quality standards are detected and corrected promptly.

Finishing and Surface Treatment

After machining, we offer a range of finishing options to enhance the appearance and functionality of the parts. This includes polishing, grinding, anodizing, plating, and painting.

Packaging and Shipping

The finished parts are carefully packaged to protect them during transit. We use appropriate packaging materials and methods to ensure that your parts arrive at your destination in perfect condition.

Customer Support

Our customer support team is always ready to assist you throughout the entire process.

Technical Consultation

We offer free technical consultation to help you with your design and machining requirements. Our experts can provide advice on material selection, design optimization, and machining processes.

Project Tracking

We provide real-time project tracking, allowing you to stay informed about the progress of your order. You can access detailed information about each stage of the production process through our online portal.

After-Sales Service

Our commitment to your satisfaction extends beyond the delivery of your parts. If you have any issues or questions after receiving your order, our after-sales service team is here to help.

If you are interested in our CNC machining services or have any questions, please feel free to contact us. We look forward to working with you and providing you with high-quality machined parts.

[Contact Information: Company Name, Address, Phone Number, Email Address]