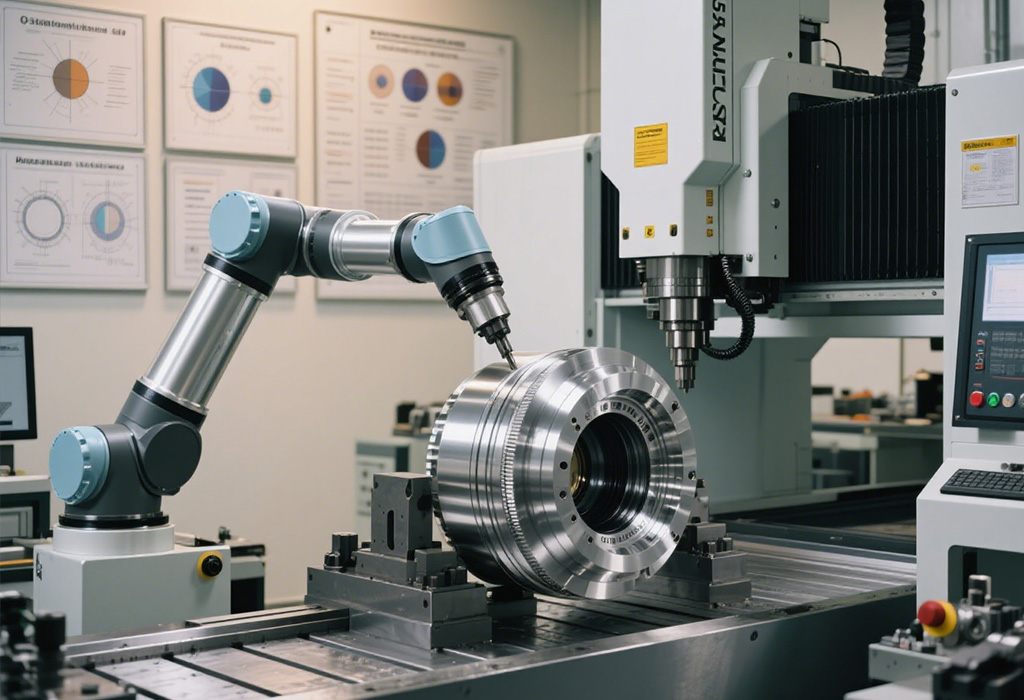

Comprehensive Service Capabilities

Table 1: CNC Machining Equipment & Technical Specifications.

|

Category |

Details |

Key Specifications |

|

Machine Types |

5-axis CNC machining centers (DMG MORI HSC 75 linear) |

Over 60 units of equipment |

|

Material Range |

Metals: Aluminum 6061/7075-T6, SS 304/316/17-4PH, Titanium Grade 5, Brass C36000 |

Aerospace-grade materials (AMS 4928) |

|

Processing Range |

Max milling size: 1500mm × 1000mm × 800mm |

5-sided machining in single setup |

|

Precision Tolerance |

Machining tolerance: ±0.005mm (5-axis) – ±0.05mm (3-axis) |

ISO 2768-mk compliance |

|

Post-Processing |

Anodizing (Type II/III hard coat), Powder coating, Nickel chrome plating |

ASTM B580 plating standards |

Industry Applications & Case Studies

Table 2: Typical Components & Technical Achievements.

| Industry | Common Components | Technical Highlights |

| Aerospace | Turbine blade hubs, Landing gear brackets, Avionics housings | 28% weight reduction via topology optimization FAA DO-160G vibration compliant Ti-6Al-4V machined to ±0.01mm tolerance |

| Medical Devices | Surgical forceps, Spinal implants, MRI-compatible components | Ti-6Al-4V acetabular cups with Ra 0.4μm finish ISO 13485 cleanroom manufacturing 510(k) documentation support |

| Automotive (EV) | Battery trays, Suspension arms, Electric motor housings | Aluminum 6061-T6 trays 30% lighter than steel 5-axis machined cooling channels 10,000+ units/month production |

| Robotics | Harmonic drive gears, Robotic arm joints, Sensor mounts | Gears with ±0.003mm pitch tolerance Carbon fiber inserts for 40% backlash reduction |

| Semiconductor | Wafer carriers, Precision fixtures, Vacuum chamber components | 316L stainless steel with Ra 0.8μm finish ISO class 5 cleanroom assembly ESD-protected processes |

Production Process & Quality Assurance

Design for Manufacturability (DFM)

♦ 3D model analysis with SolidWorks/UG/NX.

♦ Tolerance stack-up simulation.

♦ Material cost optimization.

CNC Machining & In-Process Inspection

♦ 5-axis simultaneous machining for complex geometries.

♦ Renishaw in-cycle probing.

♦ Real-time SPC monitoring.

Final Quality Control

♦ Zeiss CMM inspection (±0.002mm accuracy)./ ♦ Optical projector for micro-features./ ♦ 100% visual & functional testing.

Pricing & Lead Times

|

Order Type |

Quantity Range |

Lead Time |

Pricing Factor |

|

Prototyping |

1-50 units |

3-7 days |

Material & complexity |

|

Low Volume |

50-1,000 units |

10-15 days |

Batch efficiency |

|

Mass Production |

1,000+ units |

20-45 days |

Tooling amortization |

Certifications & Compliance

Our customer support team is always ready to assist you throughout the entire process.

ISO 9001:2015 certified

AS9100D for aerospace components

ITAR registered

RoHS/ REACH compliant sourcing

Pricing & Lead Times

Email: sales@xxyuprecision.com

Tel: +86-755-27460192

Attach 3D models (STEP/IGES) for 24-hour quotes.