Comprehensive CNC Turning Capabilities

Table 1: CNC Turning Equipment and Technical Specifications.

|

Category |

Details |

Key Specifications |

|

Machine Types |

CNC Slant - Bed Turning Centers: Doosan Puma 5100, Hyundai Wia Lynx 220LSY |

Total turning equipment: 30+ advanced units |

|

Material Range |

Metals: |

Material certifications: Full traceability reports available |

|

Processing Range |

Max Turning Diameter: 500 mm |

Live Tooling: Perform milling, drilling, and tapping operations in a single setup |

|

Precision Tolerance |

Roundness: ≤ 0.001 mm |

Inspection Equipment: Zeiss Contura CMM with accuracy of ±(1.5 + L/350) μm |

|

Post - Processing |

Surface Finishing: |

Industry Standards: ASTM B580 (plating), Boeing BAC 5616 (anodizing) |

Industry Applications and Case Studies

Table 2: Typical Components and Technical Achievements.

| Industry | Common Components | Technical Highlights |

| Aerospace | Turbine Shafts, Landing Gear Bolts Actuator Rods, Engine Mounting Studs |

Material: Machined from Ti - 6Al - 4V with dimensional tolerance of ± 0.003 mm Surface Finish: Achieved Ra 0.4 μm on critical bearing surfaces Compliance: Passed FAA fatigue and stress testing requirements |

| Medical Devices | Orthopedic Implants (Screws, Pins) Surgical Instrument Handles, Cannulas |

Material: Medical - grade titanium (ASTM F136) with biocompatible surface treatment Precision: Thread pitch tolerance within ± 0.001 mm for secure assembly Cleanroom Manufacturing: ISO 13485 compliant production environment |

| Automotive | Camshafts, Crankshafts Axle Shafts, Transmission Shafts |

Material: 4140 alloy steel with quenched and tempered heat treatment Efficiency: Reduced production cycle time by 30% using high - speed turning Volume: Capable of producing 10,000+ shafts per month |

| Oil & Gas | Downhole Tool Components Valve Stems, Pump Shafts |

Material: Corrosion - resistant alloys (Inconel, Hastelloy) Feature: Machined deep internal threads with L/D ratio > 15:1 Testing: Passed NACE MR0175 sulfide stress corrosion testing |

| Electronics | Precision Connector Pins Heat Sink Spacers, Shafts for small motors |

Material: Brass with nickel plating for conductivity and durability Precision: Diameter tolerance of ± 0.002 mm for tight - fit applications Surface Finish: Electropolished to Ra 0.8 μm for enhanced electrical contact |

Production Process and Quality Assurance

Our production process is designed to maintain the highest levels of precision and consistency at every stage.

Design Review and Process Planning

We start by conducting a thorough Design for Manufacturability (DFM) analysis using advanced software like SolidWorks and CAMWorks. This helps us optimize toolpaths, select the most suitable materials, and design custom fixtures to ensure secure part holding during machining.

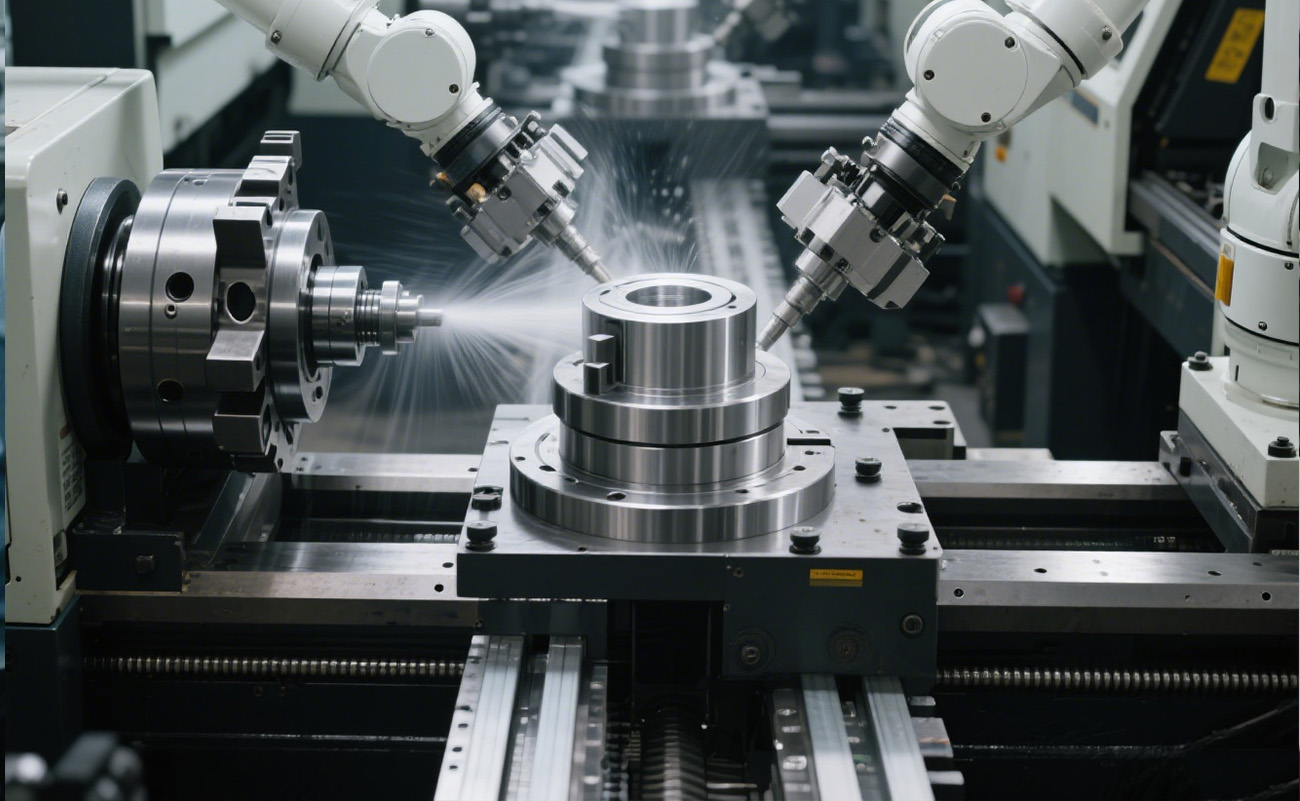

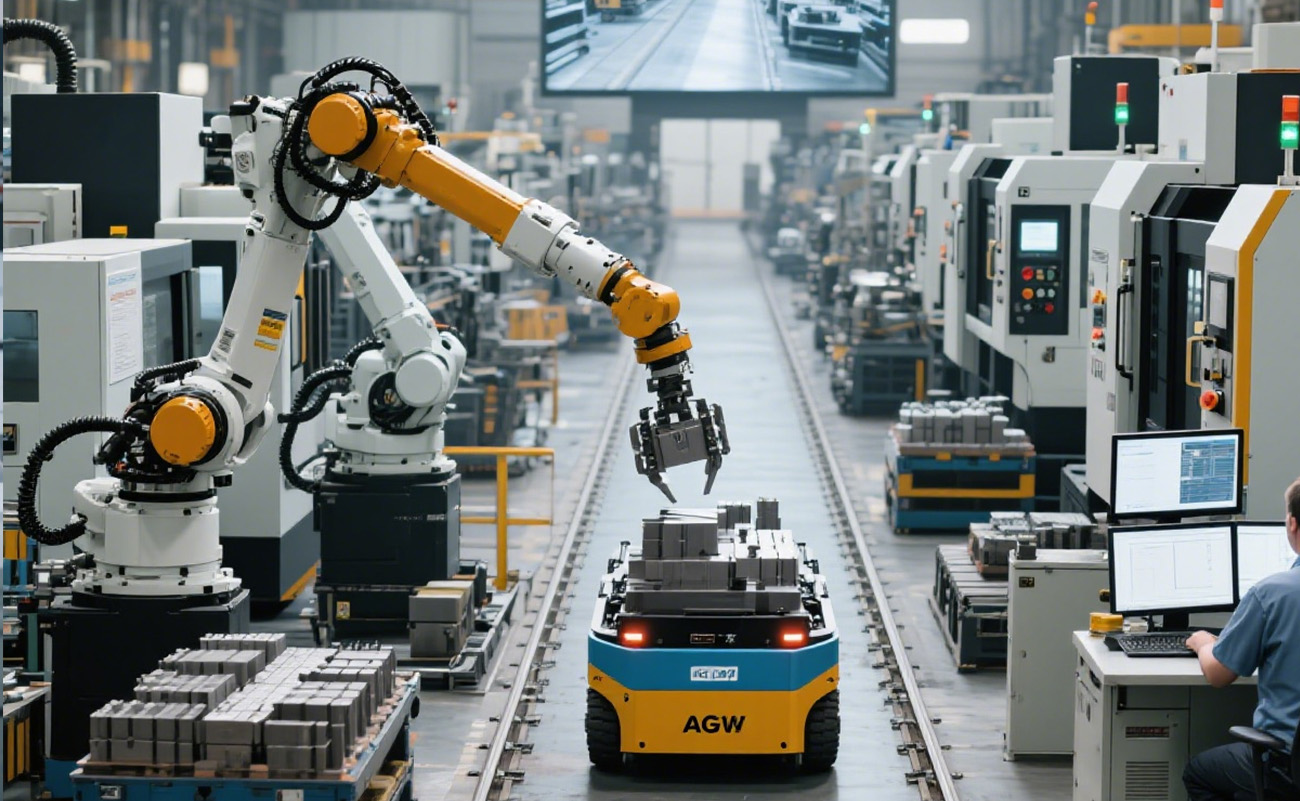

CNC Turning and In - Process Monitoring

Our automated machining systems, equipped with bar feeders and robotic loaders, enable continuous production of identical parts. Renishaw in - cycle probes are used to measure dimensions in real - time, allowing for immediate adjustments. Statistical Process Control (SPC) techniques are applied to monitor key machining parameters, ensuring consistent quality throughout production.

Final Inspection and Quality Control

Every component undergoes a rigorous inspection process. We use a Zeiss Contura Coordinate Measuring Machine (CMM) to conduct comprehensive 3D measurements, verifying all critical dimensions with high accuracy. A 100% visual inspection is also performed to check for surface defects, burrs, and finish quality. For components with specific performance requirements, we conduct additional functional tests, such as torque, hardness, and fatigue testing.

Pricing and Lead Times

Table 2: Typical Components and Technical Achievements.

| Order Type | Quantity Range | Lead Time | Pricing Factor |

| Prototyping | 1 - 30 units | 3 - 5 business days | Material cost, complexity, and setup time |

| Low Volume | 30 - 500 units | 7 - 12 business days | Batch size, tooling requirements |

| Mass Production | 500+ units | 15 - 30 business days | Production volume, long - term material sourcing |

ISO 9001:2015 Certified Quality Management System

AS9100D Compliant for Aerospace Components

ISO 13485 Compliant for Medical Device Manufacturing

RoHS/REACH Compliant Material Sourcing

Pricing and Lead Times

Ready to bring your project to life? Contact our experienced sales team today.

Email: sales@xxyuprecision.com

Phone: +86 - 755 - 27460192

Simply attach your 3D models (STEP/IGES) or technical drawings, and we'll provide you with a detailed quote within 24 hours. Let us show you why we are the preferred CNC turning partner for businesses worldwide.