Our Service

We are a leading provider of injection services, specializing in the production of high-quality plastic injection molded parts. With state-of-the-art injection molding machines and a team of experienced technicians, we offer comprehensive solutions for various industries. Our commitment to precision, efficiency, and customer satisfaction has enabled us to build long-term relationships with clients worldwide.

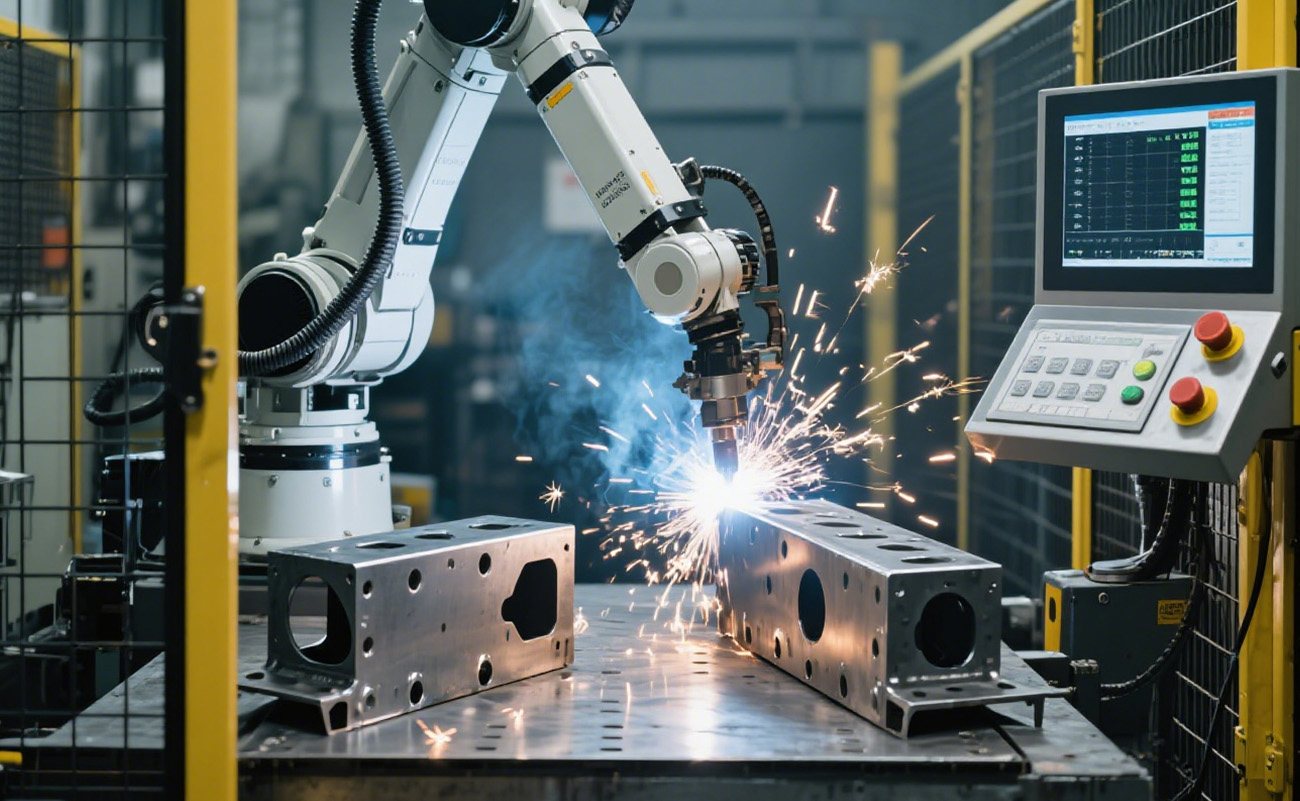

[Insert a high-quality image of our modern injection molding facility here, showing the rows of advanced injection machines and the clean, organized production area. Link the image to a page with a detailed virtual tour of the facility, including information about the machine models, clamping forces, injection capacities, and other technical specifications.]

Capabilities

Injection Molding Process

Our injection molding process is highly precise and reliable. We can handle a wide range of plastic materials, from commodity plastics like ABS and PP to engineering plastics such as PC and PEEK. Our machines are equipped with advanced control systems to ensure consistent part quality and repeatability.

[Show an animated GIF or a short video clip of the injection molding process in action, highlighting the steps from material melting and injection into the mold to the cooling and ejection of the finished part. Link the video to a page that explains the injection molding process in detail, including the role of temperature, pressure, and injection speed in achieving optimal part quality.]

Mold Design and Engineering

Our injection molding process is highly precise and reliable. We can handle a wide range of plastic materials, from commodity plastics like ABS and PP to engineering plastics such as PC and PEEK. Our machines are equipped with advanced control systems to ensure consistent part quality and repeatability.

[Show an animated GIF or a short video clip of the injection molding process in action, highlighting the steps from material melting and injection into the mold to the cooling and ejection of the finished part. Link the video to a page that explains the injection molding process in detail, including the role of temperature, pressure, and injection speed in achieving optimal part quality.]

Secondary Operations

In addition to injection molding, we provide a variety of secondary operations to enhance the functionality and appearance of your parts. This includes trimming, degating, surface finishing (such as painting, plating, and texturing), and assembly.

[Insert images of different secondary operation processes, such as a worker trimming excess material from a molded part, a part being painted in a spray booth, and an assembled product made up of multiple injection molded components. Link each image to a page that describes the specific secondary operation in detail, including the techniques, equipment used, and quality control measures.]

Materials We Work With

We have extensive experience working with a diverse range of plastic materials, each selected based on its unique properties and suitability for different applications.

| Material | Properties | Common Applications |

| ABS (Acrylonitrile Butadiene Styrene) | Good impact resistance, toughness, and surface finish. Easily machinable and painted. | Consumer electronics, toys, automotive interior parts. [Link "ABS" to a page with detailed information about its chemical composition, mechanical properties, processing characteristics, and typical applications in our injection molding process.] |

| PP (Polypropylene) | Lightweight, chemical resistant, and has a high melting point. Good for food contact applications. | Packaging, household items, medical devices. [Link "PP" to a page that explores its properties, such as its resistance to acids and bases, its recyclability, and how we optimize the injection molding process for PP.] |

| PC (Polycarbonate) | High strength, transparency, and heat resistance. Impact resistant and dimensionally stable. | Safety glasses, optical lenses, electrical enclosures. [Link "PC" to a page discussing its excellent optical clarity, flame retardant properties, and the challenges and solutions in injection molding PC parts.] |

| PEEK (Polyether Ether Ketone) | Exceptional heat resistance, chemical inertness, and mechanical strength. Biocompatible for some applications. | Aerospace, automotive under-the-hood components, medical implants. [Link "PEEK" to a page with in-depth information about its high-performance properties, its compatibility with sterilization methods, and our expertise in processing this advanced material.] |

| PVC (Polyvinyl Chloride) | Good chemical resistance, electrical insulation properties, and can be rigid or flexible depending on formulation. | Plumbing pipes, wire insulation, vinyl records. [Link "PVC" to a page that details its different formulations, its environmental considerations, and our injection molding capabilities for PVC.] |

[For each material, insert a high-resolution image of the raw material pellets and a photo of a finished injection molded part made from it. The image of the finished part can be linked to a page with a case study showing how we used the material to manufacture the part, its performance in the end application, and any special considerations during the injection process.]

Quality Assurance

Quality is of utmost importance in our injection service. We have implemented a strict quality control system to ensure that every part meets or exceeds your expectations.

Incoming Material Inspection

All incoming plastic materials are thoroughly inspected for quality and consistency. We use advanced testing equipment such as spectrometers and melt flow index testers to verify material properties and ensure they meet our strict standards.

[Show an image of our quality control technicians testing the incoming plastic pellets. Link this to a page that lists the testing equipment we use, the standards we follow for material inspection, and the procedures for handling non-conforming materials.]

Process Monitoring and Control

During the injection molding process, we continuously monitor key parameters such as temperature, pressure, and cycle time. Our machines are equipped with sensors and data acquisition systems that allow us to detect any deviations and make immediate adjustments to maintain part quality.

[Display a screenshot of our process monitoring software interface, showing the real-time data of a production run. Link it to a page that explains how we use this data to control the injection process, the alarm thresholds we set, and the corrective actions we take in case of process abnormalities.]

Dimensional Inspection

We conduct precise dimensional inspections of every finished part using advanced measuring tools such as coordinate measuring machines (CMMs) and gauges. This ensures that all parts are within the specified tolerances.

[Insert an image of a CMM measuring an injection molded part. Link it to a page that describes our dimensional inspection procedures, the accuracy of our measuring equipment, and how we handle parts that do not meet the dimensional requirements.]

Visual Inspection and Quality Audits

We conduct precise dimensional inspections of every finished part using advanced measuring tools such as coordinate measuring machines (CMMs) and gauges. This ensures that all parts are within the specified tolerances.

[Insert an image of a CMM measuring an injection molded part. Link it to a page that describes our dimensional inspection procedures, the accuracy of our measuring equipment, and how we handle parts that do not meet the dimensional requirements.]

Certification and Traceability

We provide detailed inspection reports and certifications for each order, documenting the quality control process. Our traceability system allows you to track each part back to its raw material lot and production batch, ensuring complete transparency and accountability.

[Show an example of a quality inspection report and certification. Link the report to a page where customers can access their specific reports and learn more about our traceability system.]

Production Process

Project Consultation and Design

We start by understanding your project requirements and providing technical advice on material selection, part design, and mold feasibility. Our engineers work closely with you to optimize the design for manufacturability and cost-effectiveness.

[Display a flowchart or a diagram showing the steps of our project consultation and design process. Link it to a page that explains how we collaborate with customers during this stage, the tools and techniques we use for design optimization, and the typical lead times for design approval.]

Mold Fabrication

Once the design is finalized, we manufacture the molds in our precision mold-making facility. We use high-quality tool steels and advanced machining techniques to ensure the molds are accurate, durable, and have a long service life.

[Insert images of the mold-making process, including CNC machining of the mold cavities and cores, EDM (Electrical Discharge Machining) for fine details, and the assembly and polishing of the molds. Link each image to a page that describes the specific mold-making process step, the equipment and tools used, and the quality control measures during mold fabrication.]

Injection Molding Production

The molds are then installed in our injection molding machines, and the production process begins. We carefully set the process parameters based on the material and part requirements to ensure consistent quality and high productivity.

[Show a series of images or a time-lapse video of the injection molding production line in operation, from material loading to the packaging of the finished parts. Link it to a page that details the production process flow, the capacity and efficiency of our injection machines, and the production scheduling and capacity planning.]

Quality Inspection and Sorting

As mentioned earlier, each part undergoes a comprehensive quality inspection. The parts are sorted according to their quality status, with only the parts that meet our strict quality standards being packaged and shipped to our customers.

[Insert an image of the quality inspection and sorting area, with inspectors checking the parts and placing them in different bins according to their quality. Link it to a page that describes our sorting criteria, the handling of rejected parts, and the rework procedures if applicable.]

Packaging and Shipping

The finished parts are carefully packaged using appropriate packaging materials to protect them during transit. We work with reliable shipping partners to ensure timely and safe delivery of your orders.

[Show an image of the packaged parts ready for shipping. Link it to a page about our packaging and shipping procedures, including the types of packaging materials we use, the shipping methods available, and the estimated delivery times for different regions.]

Customer Support

Our customer support team is dedicated to providing you with excellent service throughout your project.

Technical Consultation

We offer technical support to help you with any questions or issues related to the injection molding process, materials, or part design. Our experts are available to provide advice and solutions to ensure the success of your project.

[Show an image of a customer service representative answering a technical question over the phone or via email. Link this to a page where customers can submit their technical inquiries and get prompt responses from our experts.]

Project Tracking

We provide real-time project tracking, allowing you to stay informed about the progress of your order. You can access detailed information about each stage of the production process through our online portal.

[Display a screenshot of our project tracking portal. Link it to the actual portal where customers can log in and track their projects, view production schedules, inspection reports, and shipping details.]

After-Sales Service

Our commitment to your satisfaction doesn't end with the delivery of your parts. If you encounter any problems with the parts or have any further requirements, our after-sales service team is here to assist you.

[Insert a testimonial from a satisfied customer about our after-sales service. Link it to a page with more customer testimonials and our approach to after-sales support, including warranty policies and procedures for handling customer complaints.]

If you are interested in our injection services or have any questions, please feel free to contact us. We look forward to working with you and providing you with high-quality injection molded parts.

[Contact Information: Company Name, Address, Phone Number, Email Address]

This page layout combines text, images, videos, and tables to provide a comprehensive and engaging overview of our injection service. The sub-links and detailed pages offer in-depth information for customers who want to learn more about specific aspects of our service, while the visual elements enhance understanding and showcase our capabilities. You can further customize and expand upon this content to meet your specific business needs and branding requirements.