Coordinate Measuring Machines (CMMs) - 3D Measuring Powerhouses

Also known as 3 - Dimensional Measuring Machines (CMMs), our CMMs are the linchpin of our inspection regimen. As depicted in the image below, they are highly accurate devices capable of measuring a part's dimensions with micron - level precision.

CMMs find extensive applications across diverse industries, from aerospace to medical. In aerospace, they are employed to inspect critical components like turbine blades, ensuring that even the minutest dimensions are within the specified tolerances. In the medical field, they verify the accuracy of surgical instruments and implant components.

| Specification | Details |

| Measuring Range | [X] mm (Length) x [Y] mm (Width) x [Z] mm (Height), adaptable to various part sizes |

| Accuracy | Up to ±0.001 mm, providing extremely precise measurements |

| Probe Types | Equipped with touch - trigger probes for general measurements and scanning probes for complex surface profiling |

| Software Compatibility | Integrates with industry - leading metrology software for data analysis and reporting |

Coordinate Measuring Machines (CMMs) - 3D Measuring Powerhouses

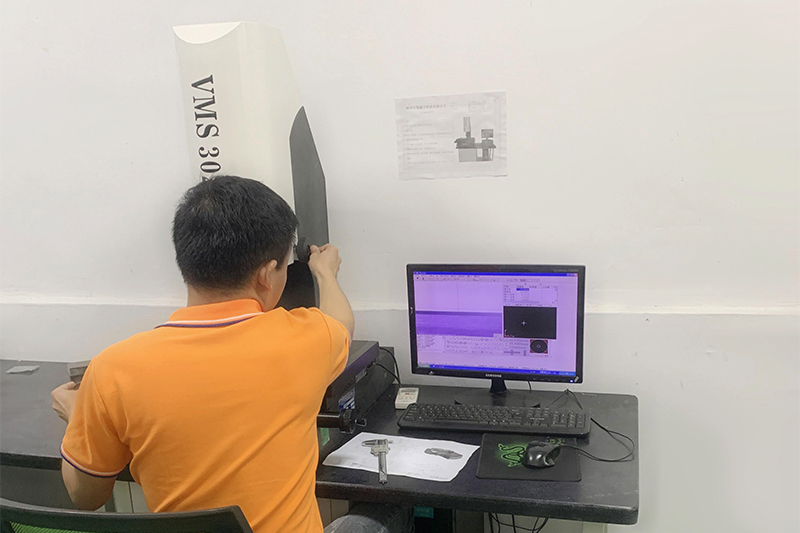

Optical comparators are indispensable for non - contact inspection of parts. The image showcases the working principle of an optical comparator, where the part is magnified and projected onto a screen for measurement.

These are particularly useful in the electronics industry, where small and intricate components need to be inspected. For instance, they can be used to measure the dimensions of micro - connectors or the alignment of circuit board traces. In the tool - and - die industry, optical comparators are used to check the accuracy of molds and dies.

| Specification | Details |

| Magnification Range | From [Min magnification]x to [Max magnification]x, adjustable for different part sizes and inspection requirements |

| Image Resolution | High - resolution imaging, allowing for clear visualization of fine details |

| Measuring Accuracy | ±0.005 mm for linear measurements, ensuring reliable results |

| Illumination System | Features variable - intensity and multi - angle illumination to enhance part visibility |

Digital Height Gauges - Precise Vertical Measurements (2.5D Projector)

Digital height gauges, often referred to as 2.5 - Dimensional Measuring Tools, play a crucial role in our inspection process. The image below shows a digital height gauge in use, measuring the height of a workpiece with precision.

These gauges are widely used in manufacturing settings to measure the height, depth, and step - heights of parts. They are especially valuable in the production of precision - machined components, such as those found in the automotive and semiconductor industries.

| Specification | Details |

| Measuring Range | [Min height] - [Max height] mm, suitable for a wide range of part heights |

| Accuracy | ±0.01 mm, providing reliable vertical measurements |

| Display Type | Digital display for easy reading and data recording |

| Probe Options | Available with different probe tips for various surface types |

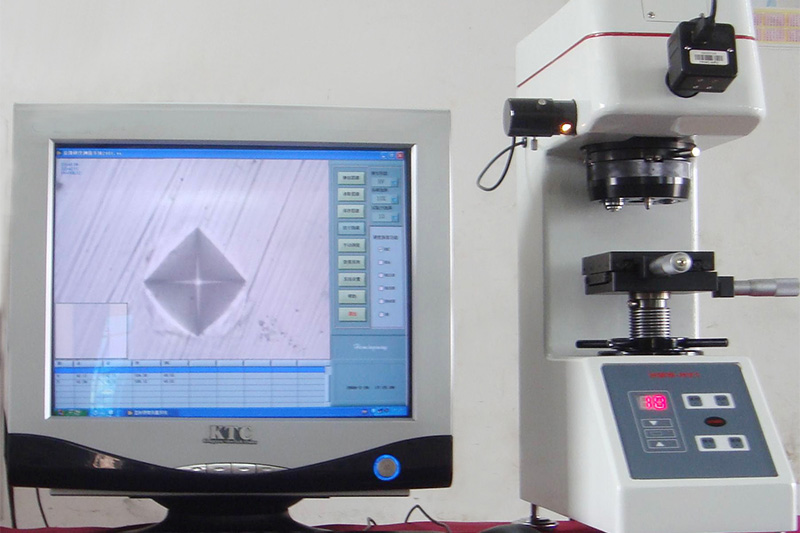

Hardness Testers

Hardness testing is essential for ensuring the quality of materials used in our machining processes. The image below shows a hardness tester being used to measure the hardness of a metal sample.

In the metalworking industry, hardness testing helps in verifying the quality of raw materials and finished components. For example, in the production of gears, hardness testing ensures that the material can withstand the high loads and stresses during operation. We utilize different types of hardness testers, including Rockwell, Brinell, and Vickers, to accommodate diverse materials and testing requirements.

| Specification | Details |

| Hardness Scale Coverage | Rockwell: A, B, C scales; Brinell: HBW scale; Vickers: HV scale |

| Testing Force Range | Adjustable testing forces to suit different material hardness levels |

| Indenter Types | Equipped with appropriate indenters for each hardness scale |

| Accuracy | High - accuracy measurements, within ±[X] hardness units depending on the scale |

Surface Roughness Testers

Surface roughness is a critical factor in many applications, and our surface roughness testers are designed to measure this parameter accurately. The image shows a surface roughness tester in use, scanning the surface of a machined part.

In industries such as automotive and manufacturing, surface roughness can impact the performance and durability of components. For example, in engine components, a proper surface finish can reduce friction and enhance efficiency. Our surface roughness testers can measure various roughness parameters, such as Ra (arithmetical mean deviation of the assessed profile) and Rz (average height of the five highest peaks and the five deepest valleys within the evaluation length).

| Specification | Details |

| Measuring Range | Ra: [Min Ra value] - [Max Ra value] µm, suitable for a wide range of surface finishes |

| Sensor Type | High - precision stylus sensors for accurate surface profiling |

| Sampling Length | Adjustable sampling length to meet different industry standards |

| Data Output | Can output data in various formats for easy integration with quality control systems |

Microscopes

Microscopes are invaluable for inspecting minute details on the surface of parts. The image below shows a microscope being used to examine a component at a high magnification.

In the electronics and jewelry industries, microscopes are used to inspect the quality of soldering joints, the surface finish of precious metals, and the integrity of micro - components. They enable our inspection team to detect defects and imperfections that are invisible to the naked eye.

|

Specification |

Details |

|

Magnification Range |

From [Min magnification]x to [Max magnification]x, allowing for detailed inspection at different levels |

|

Illumination System |

Equipped with bright LED illumination for clear visibility of the specimen |

|

Image Capture Capability |

Some models support image capture for documentation and analysis |

|

Focus Adjustment |

Precise focus adjustment for sharp imaging at different depths |

Micrometers

Micrometers are precision - measuring instruments used for taking extremely accurate linear measurements. The image below shows a micrometer being used to measure the diameter of a cylindrical part.

They are commonly used in machining operations to measure the diameter of shafts, the thickness of materials, and the depth of holes. Micrometers are known for their high accuracy and are an essential tool in any precision - manufacturing environment.

| Specification | Details |

| Measuring Range | [Min measurement] - [Max measurement] mm, available in different ranges for various applications |

| Accuracy | ±0.001 mm, providing highly precise linear measurements |

| Anvil and Spindle Design | Precision - ground anvils and spindles for consistent and reliable measurements |

| Locking Mechanism | Equipped with a locking mechanism to hold the measurement in place |

Calipers

Calipers are versatile measuring tools that can be used to measure the internal, external, and depth dimensions of parts. The image below shows a digital caliper being used to measure the width of a part.

They are widely used in a variety of industries, from woodworking to metal fabrication. Calipers offer a convenient and accurate way to take quick measurements during the manufacturing process.

|

Specification |

Details |

|

Magnification Range |

From [Min magnification]x to [Max magnification]x, allowing for detailed inspection at different levels |

|

Illumination System |

Equipped with bright LED illumination for clear visibility of the specimen |

|

Image Capture Capability |

Some models support image capture for documentation and analysis |

|

Focus Adjustment |

Precise focus adjustment for sharp imaging at different depths |

Plug Gauges

Plug gauges are used to check the internal diameter of holes and bores. The image below shows a set of plug gauges being used to inspect a hole in a workpiece.

In the manufacturing of components such as engine cylinders, valves, and pipes, plug gauges ensure that the internal diameters meet the specified tolerances. They are simple yet highly effective tools for quality control in hole - related measurements.

| Specification | Details |

| Gauge Diameter Range | [Min diameter] - [Max diameter] mm, available in various sizes to match different hole diameters |

| Tolerance Class | Manufactured to specific tolerance classes, such as H7, H8, etc., for accurate fit verification |

| Material | Made from high - quality hardened steel for durability and wear resistance |

| Surface Finish | Smooth surface finish to prevent damage to the part being inspected |