Our Service

We are a leading provider of sheet metal services, specializing in the fabrication of high-quality metal components. With years of industry experience and a team of highly skilled professionals, we are committed to delivering precision-engineered solutions that meet the unique requirements of our clients.

Our state-of-the-art facility is equipped with advanced machinery and cutting-edge technology, enabling us to handle projects of any scale and complexity.

Capabilities

Laser Cutting

Our high-powered laser cutting machines offer exceptional precision and accuracy. We can cut a wide range of sheet metals, including stainless steel, carbon steel, aluminum, and brass, with thicknesses up to [X] mm. The laser cutting process ensures clean, smooth edges and intricate shapes, making it ideal for applications in industries such as aerospace, automotive, electronics, and signage.

CNC Punching

Equipped with advanced CNC punching presses, we can perform rapid and accurate punching operations. Our machines are capable of creating various hole patterns, slots, and forms with high repeatability. This process is suitable for mass production of parts with consistent dimensions, such as electrical enclosures, brackets, and chassis.

Bending and Forming

Our skilled technicians use precision bending machines to create accurate and complex bends in sheet metal. We can handle different bend radii and angles, ensuring the desired shape and fit for your components. Whether it's a simple bracket or a complex enclosure, our bending capabilities guarantee high-quality results.

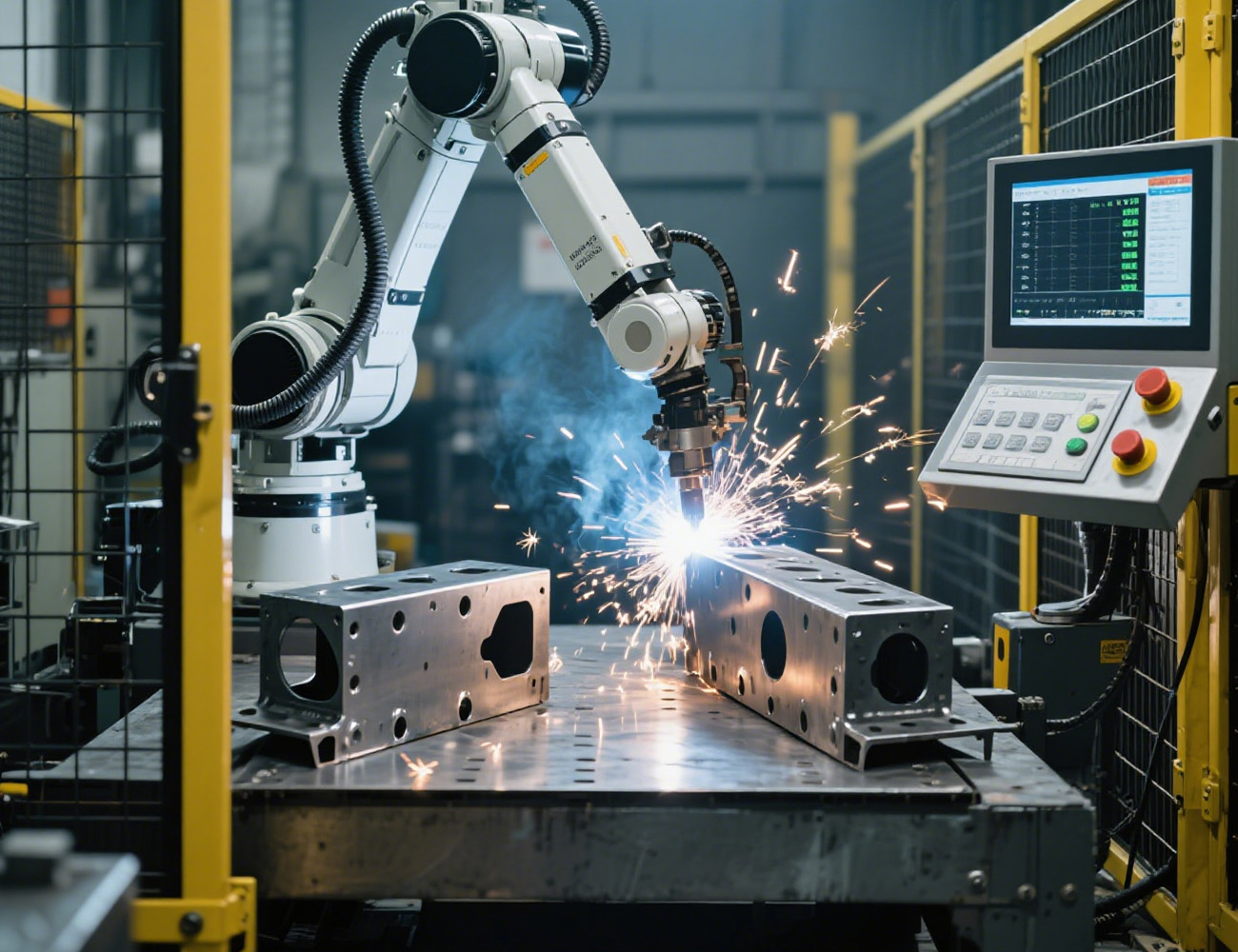

Welding and Assembly

We offer professional welding services, including MIG, TIG, and spot welding, to join sheet metal parts together. Our experienced welders ensure strong and durable welds, meeting the highest quality standards. Additionally, we provide assembly services to complete your products, from simple sub-assemblies to fully assembled units.

Surface Treatment

To enhance the appearance and durability of your sheet metal products, we offer a variety of surface treatment options, such as powder coating, painting, anodizing, and plating. These treatments not only protect the metal from corrosion but also provide a customized finish to match your specific requirements.

Materials We Work With

We work with a wide range of sheet metal materials, each selected based on its unique properties and suitability for different applications.

| Material | Properties | Common Applications |

| Stainless Steel | High corrosion resistance, strength, and durability. Good formability and weldability. | Food processing equipment, medical devices, architectural components. |

| Carbon Steel | Strong and cost-effective. Can be heat-treated for enhanced hardness and strength. | Machinery parts, automotive components, industrial equipment. |

| Aluminum | Lightweight, excellent thermal and electrical conductivity. Good corrosion resistance in certain environments. | Aerospace components, electronics enclosures, automotive parts. |

| Brass | Good machinability, corrosion resistance, and aesthetic appeal. | Decorative items, musical instruments, plumbing fittings. |

| Copper | High electrical conductivity, ductility, and thermal conductivity. | Electrical wiring, heat exchangers, roofing materials. |

Quality Assurance

Quality is at the heart of our sheet metal service. We have implemented a comprehensive quality control system to ensure that every component meets or exceeds your expectations.

Incoming Material Inspection

All incoming sheet metal materials are thoroughly inspected for thickness, hardness, surface quality, and chemical composition. We only accept materials that meet our strict quality standards, ensuring the integrity of the final product.

Process Inspection

During each stage of the fabrication process, from cutting to bending and welding, our technicians perform in-process inspections. We use precision measuring tools and gauges to verify the dimensions and tolerances of the parts, making immediate adjustments if necessary.

Final Inspection

Before shipping, every finished product undergoes a detailed final inspection. This includes a visual inspection for cosmetic defects, dimensional checks using advanced measurement equipment, and functional testing if required. Only products that pass our rigorous inspection are released to the customer.

Certification and Traceability

We provide detailed inspection reports and certifications for each order, documenting the quality control process and the materials used. Our traceability system allows us to track each part back to its source, ensuring complete transparency and accountability.

Production Process

Design and Engineering

Our team of experienced engineers works closely with you to translate your ideas into manufacturable designs. We use the latest CAD/CAM software to create 3D models and generate optimized production drawings, ensuring the best possible outcome for your project.

Material Preparation

Once the design is approved, we select the appropriate sheet metal material and cut it to the required size and shape using our laser cutting or CNC punching machines. The cut pieces are then carefully deburred and cleaned to prepare them for the next stage.

Machining Operations

The parts are loaded onto our CNC machines, and the machining process begins. Our experienced operators closely monitor the machines to ensure smooth operation and adherence to the programmed instructions. We use advanced tooling and cutting strategies to achieve high quality and efficiency.

Quality Control and Inspection

As mentioned earlier, quality inspections are carried out at various stages of the production process. We ensure that any deviations from the required quality standards are detected and corrected promptly.

Finishing and Surface Treatment

After machining, we offer a range of finishing options to enhance the appearance and functionality of the parts. This includes polishing, grinding, anodizing, plating, and painting.

Packaging and Shipping

The finished parts are carefully packaged to protect them during transit. We use appropriate packaging materials and methods to ensure that your parts arrive at your destination in perfect condition.

Customer Support

Our customer support team is always ready to assist you throughout the entire process.

Technical Consultation

We offer free technical consultation to help you select the best materials and design options for your sheet metal project. Our experts are available to answer any questions you may have regarding fabrication techniques, tolerances, and finishes.

Project Tracking

We provide real-time project tracking, allowing you to stay informed about the progress of your order. You will receive regular updates and can access detailed information about each stage of the production process through our online portal.

After-Sales Service

Our commitment to your satisfaction extends beyond the delivery of your parts. If you have any issues or questions after receiving your order, our after-sales service team is here to help.

If you are interested in our sheet metal services or have any questions, please feel free to contact us. We look forward to working with you and bringing your sheet metal projects to life.

[Contact Information: Company Name, Address, Phone Number, Email Address]